Sprue Bushing

Sprue Bushing

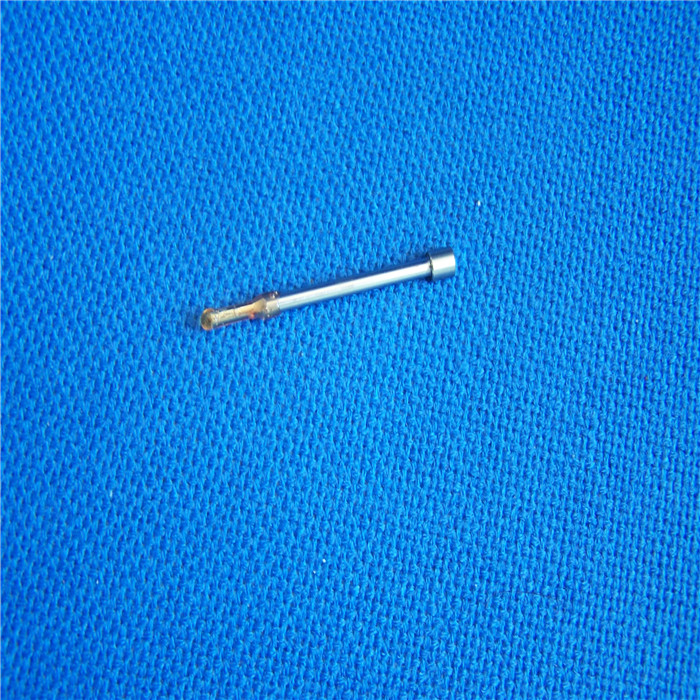

It is made of hot rolled steel,and the tapered bore is subject to precision grinding offers and ease of demoulding.

The front end can be machined to various shapes and structure.

The tapered bore of pinpoint gate has high precision and allows easy moulding.

The front end can be machined to various shapes.

The runner lock pin is of high strength and excellent wearing resistance

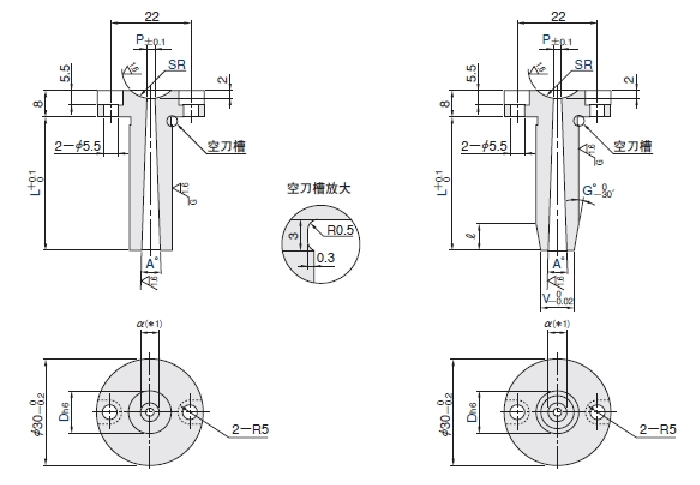

Sprue Bushing

It is made of hot rolled steel,and the tapered bore is subject to precision grinding offers and ease of demoulding.

The front end can be machined to various shapes and structure.

The tapered bore of pinpoint gate has high precision and allows easy moulding.

The front end can be machined to various shapes.

The runner lock pin is of high strength and excellent wearing resistance

SIP INDUSTRY CO., LTD

|

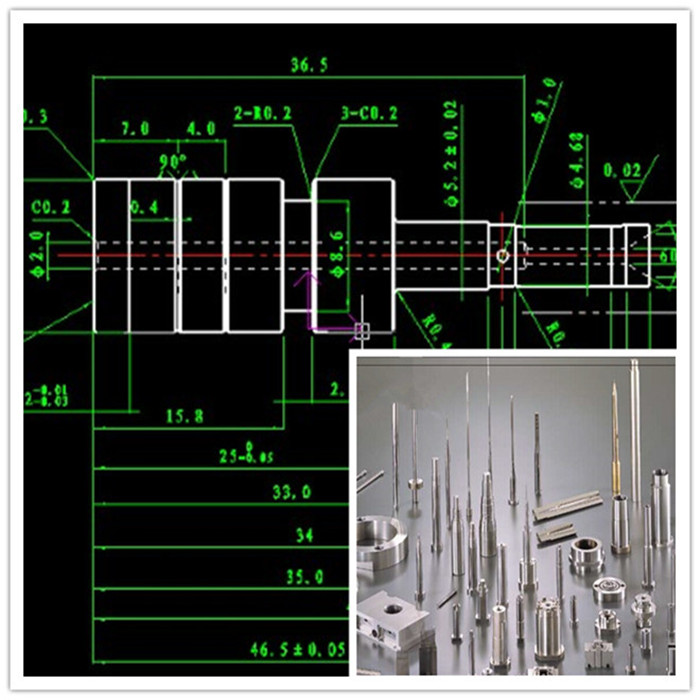

SPECIAL MOULD SPARE PARTS PRODUCTS Mostly according to special drawings ,prints, designs or samples |

Mould Spare parts

Mould and Tool Die Components Precision Mold Components punches, dies, pilot punches, guide sleeves, center pins, perforating pins, core pins, extrusion pins, stripper bushes, button dies, piercing punches, perforating punches, straight and step punches, square punches, hex size punches, ejector pins, ejector sleeve, sprue bushing, locating pins, die inserts, carbide parts, locking blocks, die core, Centre pin, Runner, lock pin, Locating ring, ejector guide pin, Support pillar, Ejector rod, Ejector guide bush…. |

| Applied in | automobile die, precision plastic mould, punch/pressing mould ,air conditioning fin die, semiconductor packaging mould, casting die |

| Processing Standards | MISUMI, PUNCH, DME, HASCO, SANKYO,

DAYTON,JIS, ISO, DIN, FIBRO, MOELLER, LANE… |

| Processing and

Testing Equipments |

Center-less grinder, surface grinder,internal

grinder, cylindrical grinder, inner-aperture grinder, Quadratic element, Sodick EDM, Mitsubishi mirror spark machines, CNC grinding machine, CNC milling machine, polishing machine, engine lathe, Projector (imported from Japan),wire EDM machine |

| Contact by Drawings with Details | 1. Drawings plus or Minus tolerances.

2. Type of material and hardness needed. 3. Quantity. 4. Target price if you have one. |

Any types interested please send inquires with detail drawings or samples!