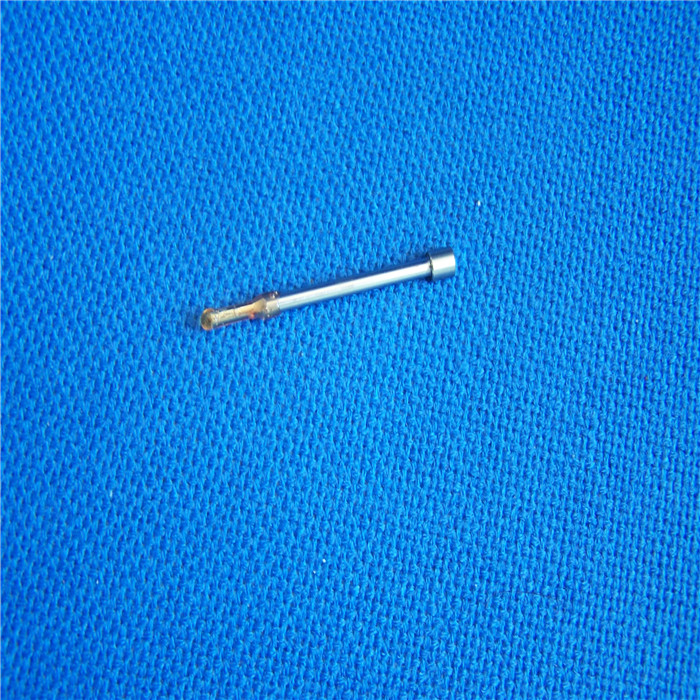

Guide Bushing

Guide Bushing

1.Material : SKD-61 / SKH-51 or as your request

2.Standard : DME, HASCO, MISUMI, PUNCH…or customized

3.Hardness: Upon request

4.Tolerance:±0.002mm

Customized is available according to your drawings or samples.

Guide Bushing

Material SUJ2, hardness above HRC58, after grinding, its dimensional

accuracy could reach 0.005mm,coaxial 0.005mm. In order to improve

its hard-wearing capability, we also can provide with MOS2 and

oilless GUIDE BUSHING of mosaic structure copper alloy.

Mainly manufacture products as followings:

ⅠPlastic mold: Ejector pin, Ejector Sleeve, Blade pin, Stepped Pin,

Rectangular Ejector Pin, Core pin …

ⅡPress die: Punches, Drill Bush , Button dies, Spure bush,

guide bush, guide pillar…

Why choose us:

1.Quality:

The technologists and workers in Sip Factory have years of experience in the mould spare parts

manufacturing ,and they can quickly judge the processing technique from a drawing ,print or sample.

When processing, first-class base materials imported or sourced from first-class materials supplier,

advanced processing grinding machine ensures perfect goods. Focus on test and quality control afterwards.

2.People:

The service people have years of experience in the overseas market and have specialized-knowledge

for most mould spare parts and can answer your questions in a quick reaction.

3.Price

Sip always offer reasonable price so as to fight in the fierce competitive market,

but without doubt, top quality.

4.Afterwards service

No matter cooperated or not, Sip will always be happy to offer you any suggestions, and

would like to share kinds of technology information to get a win-win share with our customers.

Sip will always be responsible for every products we produced and sold out, anytime ,anywhere.

Just contact ! Any inquiries will be reply within 24 hours.