roughness explanation

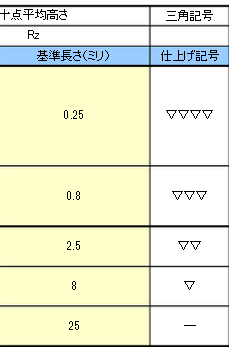

Some precision parts ask very precision in the surface,like RZ0.5,Ra0.8… Sip can achieve Rz0.0.25 by mirror polishing when produce the semicon pins and precision pins. Here is some information about the roughness and surface smooth.

Material SKH 51 and SKD11 comparison

SKH 51 and SKD11 are very often used as the COMMON steel materials to produce mould spare parts. There is some comparison for the two types of materials,customer can check and decide wich materials is better or more proper . SKH 51-M2-HSS-1.3343 1. SKH51(W6Mo5Cr4V2)has good heating hardness and toughness, and its surface hardness could reach to 59~61HRC after harderning process. 2. SKH 51 is one kind of high speed steel with molybdenum and low tungsten, and its cost is just second to W18Cr4V .It is a widely used high speed steel suitable for manufacturing drills and taps, threading die, ejector sleeves, mills, gear cutting tools, cold molds etc. 3. Property: SKH51 is one kind of high speed steel by Japanese JIS standard, widely used for its cost performance. The carbide in this steel is equally distributed and fine. It is of high toughness, good thermoplastic, excellent abrasive resistance. 4. Hardness:59-61HRC Flexural Strength: 4650~4690Mpa Compression strength:3360~3390 Mpa Tenacity: 38J/cm2 Evaluation: SKH51 is one kind of common high speed steel with the best tenacity in the high speed steel. SKD 11-D3-DC11-Cr12Mo1V-X165CrM0v12 SKD11 is one kind of tool steel, and its hardness could reach HRC 56~60 after quenching and tempering process. It is […]

Heat Treatment

Annealing,quenching,tempering,normalizing heat treatments are used to get different hardness.carburizing,nitriding and carbonitriding,TiN,TiC,TiCN.PVD(physical Vapor Deposition) and CVD(Chemical Vapor Deposition) methods. galvanic processes,wire edm,electrospark impregnation

Why Choose Sip?

1. Quality: The technologists and workers in Sip Factory have years of experience in the mould spare parts manufacturing ,and they can quickly judge the processing technique from a drawing ,print or sample. When processing,first-class base materials imported or sourced from first-class materials supplier,advanced processing…Read more